Sequencing For Making Flanged Windows Airtight

Flanged windows are ubiquitous in American construction. As we push toward higher levels of enclosure performance;- with increased insulation levels, airtightness and vapour control;- window specifications are getting more robust too. And while it can be a relatively straightforward thing to select a better window, it isn't so readily clear how to match it with a better installation.

Let's make a high performance installation too Download the guide here (PDF).

Simple is Better

It needn't be complicated.

There are a few key concepts that guide us:

- Absolute control layer continuity: of water, air, insulation, and vapour control - from component to component.

- Maximize drying potential, to build drying reserves and a safety buffer. In cold and mixed climates this means vapour open toward exterior and vapour variable toward interior.

- Durable and cost effective: with quality components, properly installed, the installation should exceed the life of the windows, no call backs and no up-charges.

Armed with these three commandments, we breakdown, tweak, and repackage the familiar steps of installing a flanged window.

Outboard

The WRB is a high-performance three layer monolithic membrane;- SOLITEX Mento 1000: waterproof, airtight and vapour open. We make connections in a weather-lapped fashion, always starting at the bottom and overlapping materials as we work up, assuring proper drainage EXTOSEAL Encors, a self-sealing, highly form fitting butyl-acrylic adhesive forms the sill pan. Face tape with; CONTEGA SOLIDO EXO*, a vapour open, airtight and waterproof SOLID acrylic adhesive with highly form-fitting fleece backing. One may also face tape with; TESCON Vana, waterproof, airtight and vapour permeable all-around SOLID acrylic tape.

*CONTEGA SOLIDO EXO has since been replaced in our product offerings by CONTEGA SOLIDO IQ

DO NOT FACE TAPE WITH vapour IMPERMEABLE TAPE: IT DAMS MOISTURE IN THE WALL

Because the WRB is our outboard airtight layer the connection to the flange and window must be continuous all the way around - this includes at the sill and heads. We are making a waterproof enclosure so moisture intrusion should be minimal, but in case there is some moisture intrusion, the vapour permeable nature of the flat taping assures drying capability and protection from damages.

Inboard

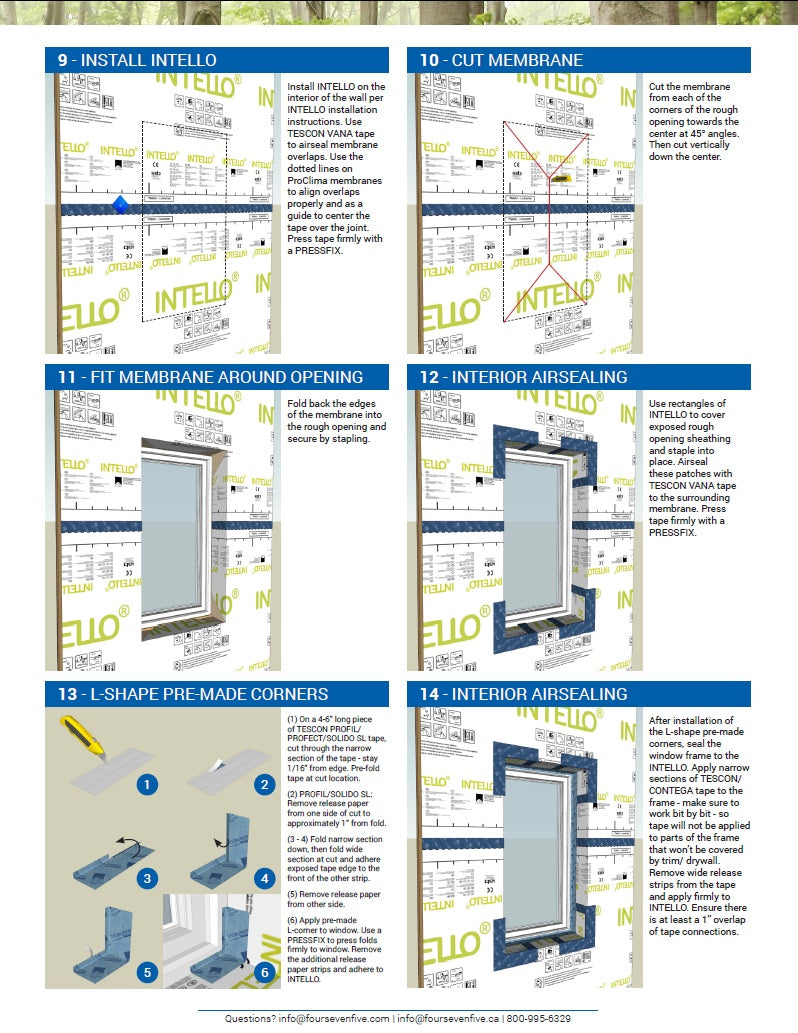

If the framing cavity is insulated, there should be an airtight and vapour variable control layer inboard of the insulation. INTELLO Plus is the most robust smart vapour retarder available and is extremely airtight. Connecting the membrane to the window becomes essential - for moisture protection, comfort and efficiency. We make these connections with TESCON Profect or Profil tapes. With split release paper backing, these tapes are made for making tight inside corner connections. We show how to premake corners so that these tightest of spots are successfully dealt with.

Download the Guide

We hope you find this step-by-step instruction guide useful. DOWNLOAD HERE (PDF).Complete your high-performance enclosure with with a high performance flanged window install.