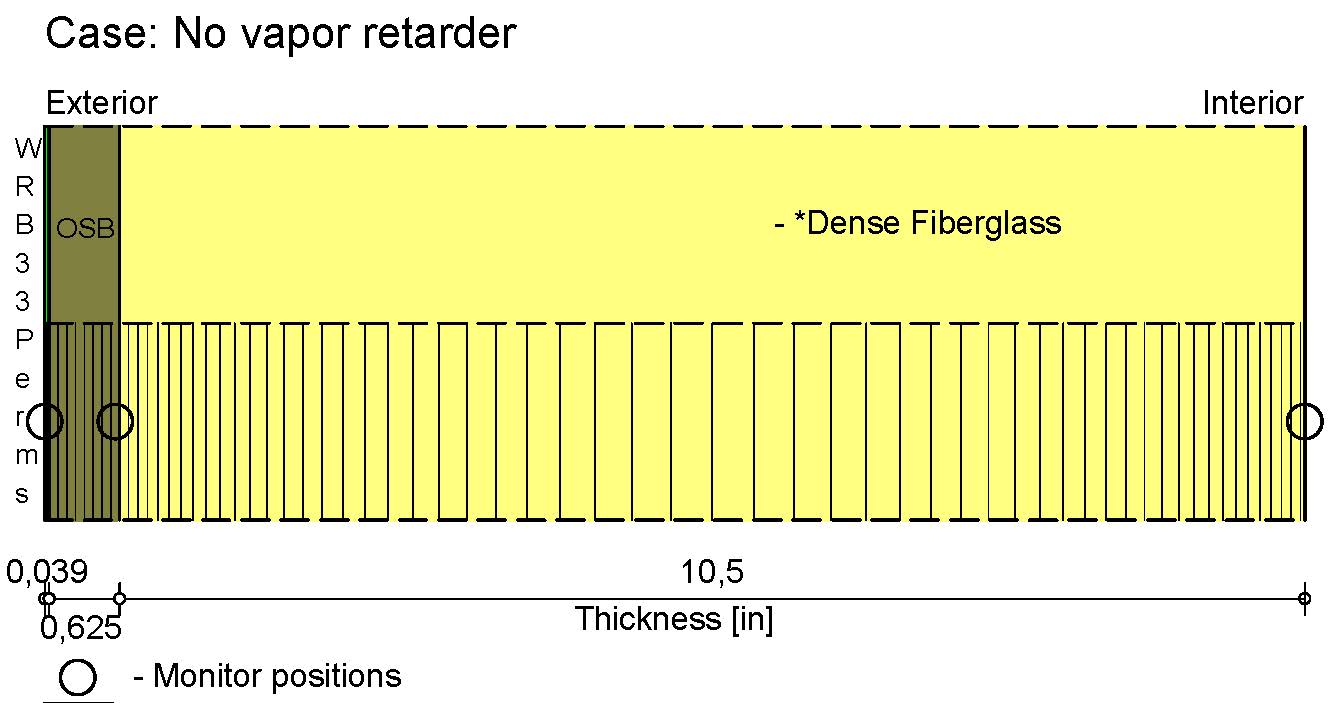

Double-stud walls have become a popular and cost efficient way to build well-insulated envelopes: two 2x4's spaced apart easily makes a R-40+/10.5" thick wall. Such walls also include a thermal break and can be insulated with densepacked cellulose or fiberglass, both quickly and affordably.

But how do they manage moisture? Let us investigate with WUFI Pro modeling. (WUFI Pro provides hourly hygrothermal modeling based on interior and exterior climates and material inputs.)

One of the concerns with such double-stud walls is that they add very large amounts of insulation on the inside of exterior structural sheathing. This sheathing is generally a class II/low III vapour retarder - WUFI uses perm/in of OSB that varies between 0.2 and 3 perms. The question is: will the OSB sheathing get damp, thereby increasing the chance for rot and mold? We want to keep this important structural element free from decay even when unforeseen moisture (e.g. airleaks on interior, driven rain from exterior) reaches this OSB. A large reserve in moisture buffering capacity of the OSB assures that the building remains upright for the long term, maintains good IAQ and makes our highly insulated (passive house?) walls as resilient as possible.

There is consensus among building scientists, architects, and builders designing and testing these kinds of walls that a vented rainscreen is an essential first step to keep the sheathing from becoming damp. If any moisture will reach the sheathing - be it humidity that was diffused from the interior or a rain leak through the WRB from the exterior - it must be able to dry outwards with this vented space. The building code also acknowledges this, and for code minimum walls (not well insulated, not airtight at all) it could appear to have worked in most cases. However if you are building double-stud walls -- is it still sufficient?

What moisture level is safe?

The question we need to answer first is: how dry is dry enough for the sheathing to avoid rot and mold production? Wood normally has around 12M% moisture content, and a little more humidity can't hurt. But at what point does it start to hurt? Since being published in the 1930s (Hunt and Garret, 1938) and reconfirmed in many studies since (Viitanen 1996, 1991, etc., see links at bottom), maintaining wood moisture content below 20% completely inhibits fungal development. (Note: There is much debate and uncertainty about how high above 20% the wood can reach before it hurts, as it depends on specifics of wood, the spores, and climate). 20% moisture content roughly translates into a RH above 90% on the surface of material. However, for OSB sheathing we look for a slightly lower wood M% because of the lower perm rating of wood and the higher risk of swelling/damage by glue degradation. Pro Clima, following German standards, recommends staying below 15M% (±3%) for OSB/plywood, which closely matches the APA's engineered wood handbook (2002) limit of 16% moisture content (mc) for OSB.

The question we need to answer first is: how dry is dry enough for the sheathing to avoid rot and mold production? Wood normally has around 12M% moisture content, and a little more humidity can't hurt. But at what point does it start to hurt? Since being published in the 1930s (Hunt and Garret, 1938) and reconfirmed in many studies since (Viitanen 1996, 1991, etc., see links at bottom), maintaining wood moisture content below 20% completely inhibits fungal development. (Note: There is much debate and uncertainty about how high above 20% the wood can reach before it hurts, as it depends on specifics of wood, the spores, and climate). 20% moisture content roughly translates into a RH above 90% on the surface of material. However, for OSB sheathing we look for a slightly lower wood M% because of the lower perm rating of wood and the higher risk of swelling/damage by glue degradation. Pro Clima, following German standards, recommends staying below 15M% (±3%) for OSB/plywood, which closely matches the APA's engineered wood handbook (2002) limit of 16% moisture content (mc) for OSB.

It is also critical to consider when the wood temperature falls below 40F°-50F°. Below40F° mold spores will not grow, even with high moisture content. But above50F° with high moisture content mold spores can grow. Therefore, if moisture content ever exceeds safe levels, one wants it to occur only when the temperature is well below 50F° -- another safety threshold. ASHRAE standard 160 also formalizes this as 80% Relative humidity and 30 day average temperature below 41F°.

So let's run some WUFI models for Boston, MA on walls with and without INTELLO Plus as a smart vapour retarder, and see which double-stud wall is safe, which is not, and what safety margins each assembly offers.

Fiberglass on inside of OSB/ZIP airtight double-stud wall

First up, a double-stud fiberglass-insulated wall. It will be the lowest cost high performance wall one can design or build, but we would like to know if we are not wasting our money and have to rebuild in 5-10 years because of damages, so we do a WUFI model to see if the 5/8" OSB protected by a perm 33 WRB is safe -- first without INTELLO Plus on the interior, and then with it installed on interior.

This wall has gypsum board on the interior which was modeled as the interior airtight layer. We only included diffusion driven moisture and ignored the effects of thermal bypass. If this interior air barrier becomes compromised by the homeowner or gypsum board is missing at partition walls/floor, the result will be much worse. But for argument's sake, we are ignoring those inherent flaws in airtight drywall.

So even with a perfect interior air barrier, the results below show RH on the surface of the OSB and the M% of interior 5mm of OSB exceeding 26% and staying above 20M% into late spring. The OSB surface experiences relative humidities above 95% when temperatures are far above 50F°.

Both graphs indicate that this assembly is susceptible to fungi/mold growth and associated negative effects on the structure and indoor air quality. At 475 we would like to see a safety reserve in our wall, and so the above assembly is too risky and unacceptable in our view.

Fiberglass double-stud with INTELLO Plus

A WUFI study of a double-stud assembly that uses ProClima's INTELLO Plus as a smart vapour retarder/airsealing system shows that the OSB stays below 15M% and also well below the safety threshold set by ASHRAE Standard 160. To ensure airtightness and a robust assembly, 475 advocates that the inboard airtightness layer be blower-door tested, verified, and protected.

This provides the safety buffer that we like to see. Even if there are small mistakes in the airtight layer or additional rain reaches the OSB (such as the 1% driven rain from ASHRAE 160), this wall can use its additional moisture buffering reserve to keep the sheathing in good shape before any damages start to occur -- a good characteristic for a super insulated structure that is intended to perform for decades to come.

Cellulose double-stud wall without interior vapour retarder

Double Stud Wall Detail DWG - available for free download from 475

Double Stud Wall Detail DWG - available for free download from 475

It is often noted that dense pack cellulose has a moisture buffering capacity - and CIMA states that one doesn't need a vapour barrier when using cellulose because of these properties. We think that such a blanket statement is a pretty bold claim to make, especially when we start building walls that are 10" thick and have a vapour retarding OSB sheathing on their exteriors. This study will show if ProClima INTELLO Plus makes for a more forgiving super insulated R-40+ wall.

The concern in this case again is that the exterior OSB sheathing will slow down the movement of vapour from the insulated cavity outward in winter conditions. For example, when it is 20F° outside, the vapour drive is from inside to outside by diffusion or by airleaks/convection. This is because the outside vapour pressure in winter is almost always much lower on the exterior than on the warm/comfortable interior. For instance, even when it is 100% RH outside at 20F°, the dew point is 20F° outside, while the dewpoint is 40F° inside when we have 35% RH/68F°. And because the OSB sheathing will be practically the same temperature as the exterior temperature, one could expect moisture to condense on the OSB in those conditions (a dew point or Glaser method assessment will show this).

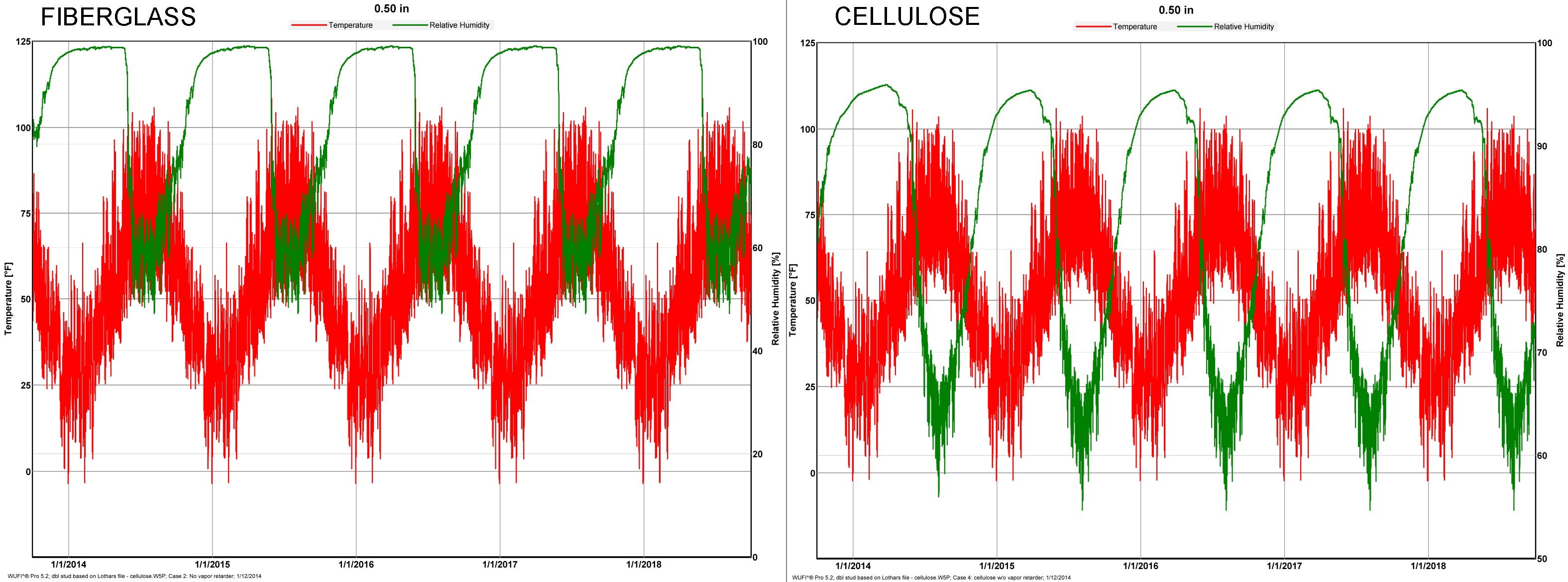

The graphs above show that indeed the moisture buffering of the cellulose helps theoretically in a diffusion-only WUFI-modeled wall. It limits the M% to just below 20, which is borderline safe, and leaves no room for error. However, the relative humidity stays above 80% for more than 30 days when the OSB temp reaches 40F° and even 50F°. This is in line with John Straube's statements in Green Building Advisor post on double-stud cellulose walls, in which he notes that monitored walls are "right on the edge between risky and where we would be safe". The monitored walls have moisture levels that are in the high 20%s and even exceed 30% in the spring. This is most likely caused by thermal bypass/convective loops/airleaks that increase OSB moisture levels above the WUFI modeled results. The GBA article then notes: The message for builders of double-stud walls is simple: don't screw up the details. “These walls are on the edge," said Straube.

Densepacked double-stud wall with ProClima INTELLO Plus

With INTELLO Plus as part of the ProClima intelligent airsealing systemon its interior, the same dense-packed 10.5" thick wallwill provide long-term airtightness (TESCON tapes have now been tested for 100 year plus performance accelerated aging) and will keep the cellulose and OSB much drier. The INTELLO pulls the assembly away from the risky edge and to safety. The graphed WUFI calculations are shown below.

The interior 3/16" analyzed slice of OSB M% settles in a fluctuating pattern between 11% and 16% through the seasons, while the relative humidity on this surface doesn't exceed 87% and actually only very briefly exceeds 80%, at a time when the sheathing is on average around 32F°. This shows that the cellulose holds on to some humidity moisture, but stays well below the safety margins given above.

Fiberglass or Cellulose?

When comparing (below) the fiberglass assembly's OSB graph with the densepacked cellulose graph (both without INTELLO), you can see that the hygroscopic properties of cellulose can help to buffer a certain amount of unforeseen moisture. This is the case that cellulose industry makes. But is that amount of buffering sufficient for a double-stud wall?

When using INTELLO Plus in each case the M% does not reach critical levels in the OSB sheathing. M% is slightly higher with cellulose (see cellulose/INTELLO graph 2 sections above) because of its hygric properties. This can be interpreted as a good thing (more buffering capacity) or a bad thing (slower drying when issues do occur). It is up to the professional to decide which insulation material property will be most important. Another option is to use mineral wool, which is not hygroscopic and will perform similarly to fiberglass, but tolerates incidental wetting to a certain extent.

Conclusion

In this post we useWUFI Pro studies toshow that double-stud walls are safer when using smart, vapour retarding INTELLO Plus. It protects any kind of fibrous insulation (hygroscopic: cellulose, woodfibers or non-hygrosopic fiberglass, mineralwool, etc.) against vapour drive from the interior in winter, while allowing inward diffusion/drying in summer. This offers architects, designers, and builders a higher safety margin by increasing the drying potential of double-stud high performance walls.

Some additional references for the 20% or lower M% limit:

Materials for Architects and Builders (Lyons 2012)

IBC recommends a max. 19% moisture content when you install sheathing.

Note:Proclima INTELLO is included in Fraunhofer material menu in WUFI Pro, including its optimized vapour variable properties (see graph below)