475 Does WUFI®: Mold Potential and Historic Masonry Retrofits in Climate Zone 6 (Burlington, VT)

A key piece of the puzzle as we decarbonize our building stock is successfully retrofitting historic masonry buildings to high performance standards that provide energy efficient operation and comfort while preserving the structural integrity of these timeless buildings for future generations. We have written often that preservationists and energy efficiency advocates need not be in opposition, but can and must work together. While freeze-thaw has been the marquee concern of such retrofits, in this post we look at the increased potential for mold growth as insulation levels rise.

But before we get to mold potential, a quick note on freeze-thaw: take a deep breath. Facade bricks freeze & thaw throughout the winter months and isn't in itself necessarily destructive. But when the masonry is saturated and freeze-thaw cycles occur, destruction results. Freeze-thaw is a real danger and installing insulation inboard can increase risk, because it makes the masonry colder and possibly wetter. But freeze-thaw is a whole systems failure where poor water management (or sometime poor masonry units) and repeated cold snaps conspire in cycles of freeze-thaw. Every building is a unique situation that must be carefully considered, but with good brick and functional facade details that sufficiently shed water, the additional risk of exterior wetting of masonry can often be sufficiently mitigated.

Which brings us to avoiding interior moisture issues at this cold brick - mold growth potential - a danger that rising insulation levels can directly effect. How is this? Because while the heightened moisture level of masonry effected by insulating is in most cases non-consequential in relation to freeze-thaw, it can contribute substantial amounts of moisture on the interior face of the masonry wall - often enough to promote mold growth.

Therefore we want to prevent condensation/moisture-increases on the inside face of the brick wall (and also optimize the thermal performance of the insulation) by first making the brick windtight and most importantly provide first class airtightness inboard of the insulation. Airtightness is the essential prerequisite for high performance construction and preventing moisture damage. We recommend to not only provide a durable, age tested, airtight layer inboard, but verify it with blower door tests. A good minimum threshold to ensure airtightness is sufficient is a blower door test goal of 0.6ACH50 - and if that is not practical because of site specific impediments - then 1 ACH50 or lower as acceptable, and 1.5 to 2 ACH50 can work - however at higher flow rates extensive leak hunting is still required (lower is always better). And as the flow rate target rises, the insulation level may want to be reduced to allow for more drying reserves.

The red dashed line in the illustration below is the airtight layer. The inboard airtight layer (see also An Interior Air Barrier Does It Better) should also be the vapour controlling layer. The most robust vapour management for masonry renovations is provided by Pro Clima INTELLO Plus smart vapour retarder and airtight membrane.

Airtight and smart vapour retarding membrane inboard of insulation prevents conditioned humid air from reaching cold masonry surfaces.

Below is a three-wythe brick wall with insulation inboard and a red dot at the point of most concern - the "first condensing surface". This is the point we'll take a close look at in our WUFI simulations./

Three-Wythe Brick wall with interior insulation

Masonry Absorbtion Test

For this case we note that the freeze-thaw danger in this assembly has been mitigated by confirming the brick rain absorption (with Karsten tubes or other methods) and restoring and supplementing all necessary water shedding details. By avoiding saturation of the exterior we can avoid freeze-thaw destruction.

Now on to the mold risk. The fundamental risk threshold for promotion of mold is defined by ASHRAE 160 which defines it as material with a 30 day running average of 80% relative humidity or higher, at 41 degrees Fahrenheit or above. With WUFI we can look at different insulation scenarios and see if this 80%RH/41F threshold is crossed, and if so, for how long .

We like to stress that not only increased interior R-values, but also vapour drive control plays a significant role in mold growth potential. The WUFI studies we did for climate zone 6 are located in the Burlington Vermont climate, on a north facing wall. Since the sun doesn't shine much on this wall it stays cold/wetter longer and thus is a conservative wall to analyze.

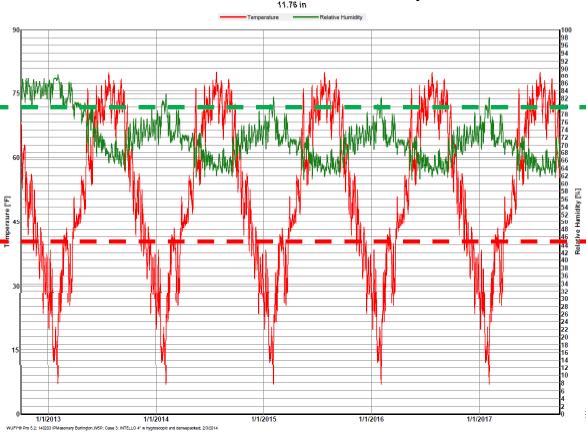

The first WUFI we show is of 4" dense-pack cellulose with hygroscopic properties* - but without a designated interior vapour retarder.

4" dense-pack cellulose without interior vapour control. The green dashed line represents the line of 80% RH and the red dashed line 41 degrees F.

We can see from this graph that long periods in each fall and spring the our red dot is above both 80% RH, while exceeding 41 degrees F for far more than 30 days - surpassing the ASHREA thresholds and exhibiting great risk for mold growth.

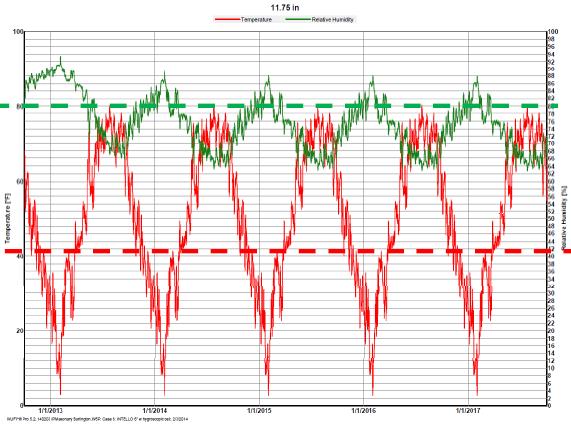

Now below, we next add INTELLO Plus smart vapour retarder inboard of the insulation and the results are dramatically different. The relative humidity is pushed below 80% practically completely, only exceeding it when the red dot is at 15F and as a result the threat of mold growth, due to insulation levels is virtually eliminated.

The same 4" of dense-pack cellulose but now with INTELLO smart vapour retarder inboard

Below the safety threshold, we can now consider to increasing our insulation levels and see how the risk increases. Below we WUFI-ed 6" of dense-pack cellulose and INTELLO Plus inboard. While the RH remains longer above 80% every winter, the temperature is well below 41 degrees during those periods and therefore the risk of mold should be minimal.

6" of dense-pack cellulose with INTELLO Plus inboard is still safe from mold risk.

Next up is 8" of dense-pack cellulose and the INTELLO Plus intelligent airtight system. This modeled assembly exceeds the ASHRAE 160 limit. The graph below indicates that the agreed upon threshold is crossed for approximately 3 days each April. Consequently based on the hypotheticals of this exercise a safe maximum insulation level would be at slightly less than 8" of hygroscopic* dense-pack cellulose with INTELLO Plus.

8" dense-pack cellulose with INTELLO Plus smart vapour retarder hits the limit in Burlington Vermont.

For the purposes of example we then ran 12" of dense-pack cellulose and we get a whopping 30 plus days above the ASHRAE threshold in both the spring and fall.

12" dense-pack cellulose even with a smart vapour retarder becomes a very high risk proposition with over 60 days a year above the ASHRAE 160 recommended limit.

While 12" of insulation is clearly unacceptable - we can conclude that in cold climates like northern Vermont, using INTELLO Plus, the most vapour variable smart vapour retarder available, in combination with hygroscopic insulation like dense-pack cellulose, and blower door tested airtightness, it is possible for one to achieve relatively high levels of insulation safely.

Thermal bridging can be substantial factor in determining effective insulation levels. Photo Credit: Building Science Corp

One last thought on how much insulation is too much. We've discussed the ideas of insulation contributing to freeze-thaw risk and mold growth risk but one should also consider the potential diminishing returns of super insulating an historic masonry building due to potential significant and widespread thermal bridging - particularly if the floors are concrete and connect to the exterior walls. Often, thermal bridges that cannot be eliminated can overwhelm the effectiveness of very high levels of wall insulation and the best "balance" is often a modest level of insulation, that is sufficient to assure indoor comfort and is combined with very good windows, doors and skylights. In each case, it is important to gauge the overall thermal performance of the complete structure, in addition to the other analyzing mold/damage risks, with as a result the determination of the most effective insulation value.

* Note that the WUFI material file for the hygroscopic dense-pack cellulose is from a German manufacturer. 475 has tried to obtain a WUFI file from National Fiber that represents the hygroscopic properties but has been unable to obtain one thus far. Therefore one key assumption we are making is that a high-quality dense-pack cellulose is used, which like the modeled German branded cellulose has hygroscopic qualities.